What is Quarter Sawn Lumber? Definition, Process, and Why It's Preferred for High-End Woodwork

Quarter sawn lumber showing distinctive linear grain pattern and ray fleck in white oak

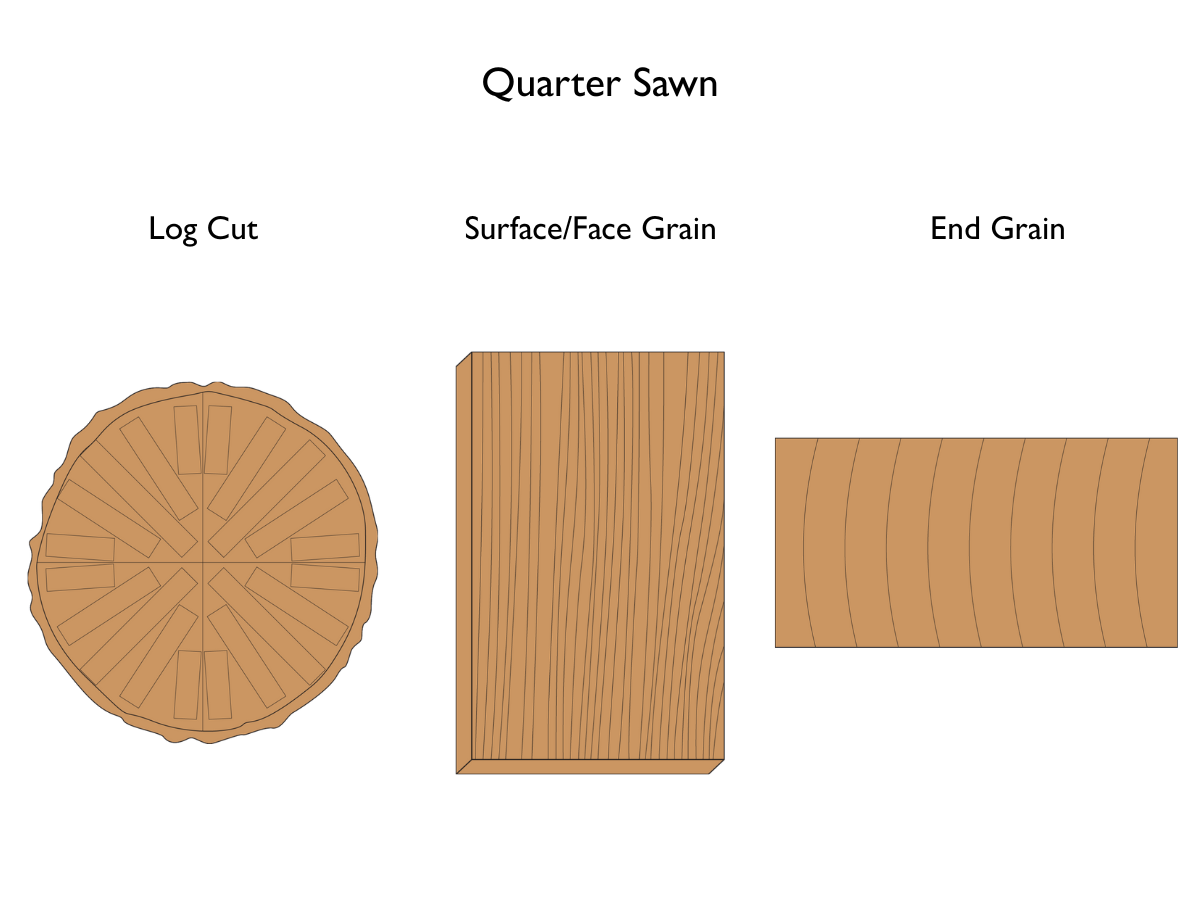

Quarter sawn lumber is sawn wood produced by cutting a log into four quarters and slicing each section at a radial angle to the growth rings. The result is narrower boards with a straight, linear grain pattern that is stronger, more stable, and less prone to cupping and surface checking compared to plain sawn lumber. In species like white oak, quarter sawing exposes medullary rays, creating decorative flecks highly valued in fine furniture, cabinetry, and flooring. Though it produces more waste than flat sawn lumber and costs more, quarter sawn wood remains one of the most recommended cuts for projects where appearance, durability, and long-term performance matter.

How Quarter Sawn Lumber Is Cut and Why It Matters

Quarter sawn lumber cutting process demonstrating how logs are cut into quarters and boards are sliced at radial angles

Quarter sawn lumber is created by cutting a log into four quarters lengthwise, then slicing boards at or near a radial angle (typically 60–90 degrees to the growth rings). This orientation produces a straight, uniform grain across the board face and results in narrower boards with superior dimensional stability.

The process yields less lumber compared to plain sawing but produces a much more stable piece. Because the growth rings are nearly perpendicular to the board's face, quarter sawn lumber is resistant to cupping, twisting, and excessive seasonal movement. The resulting lumber is especially valued in furniture, flooring, and cabinetry where precision and stability are non-negotiable.

Quarter Sawing vs Plain Sawing

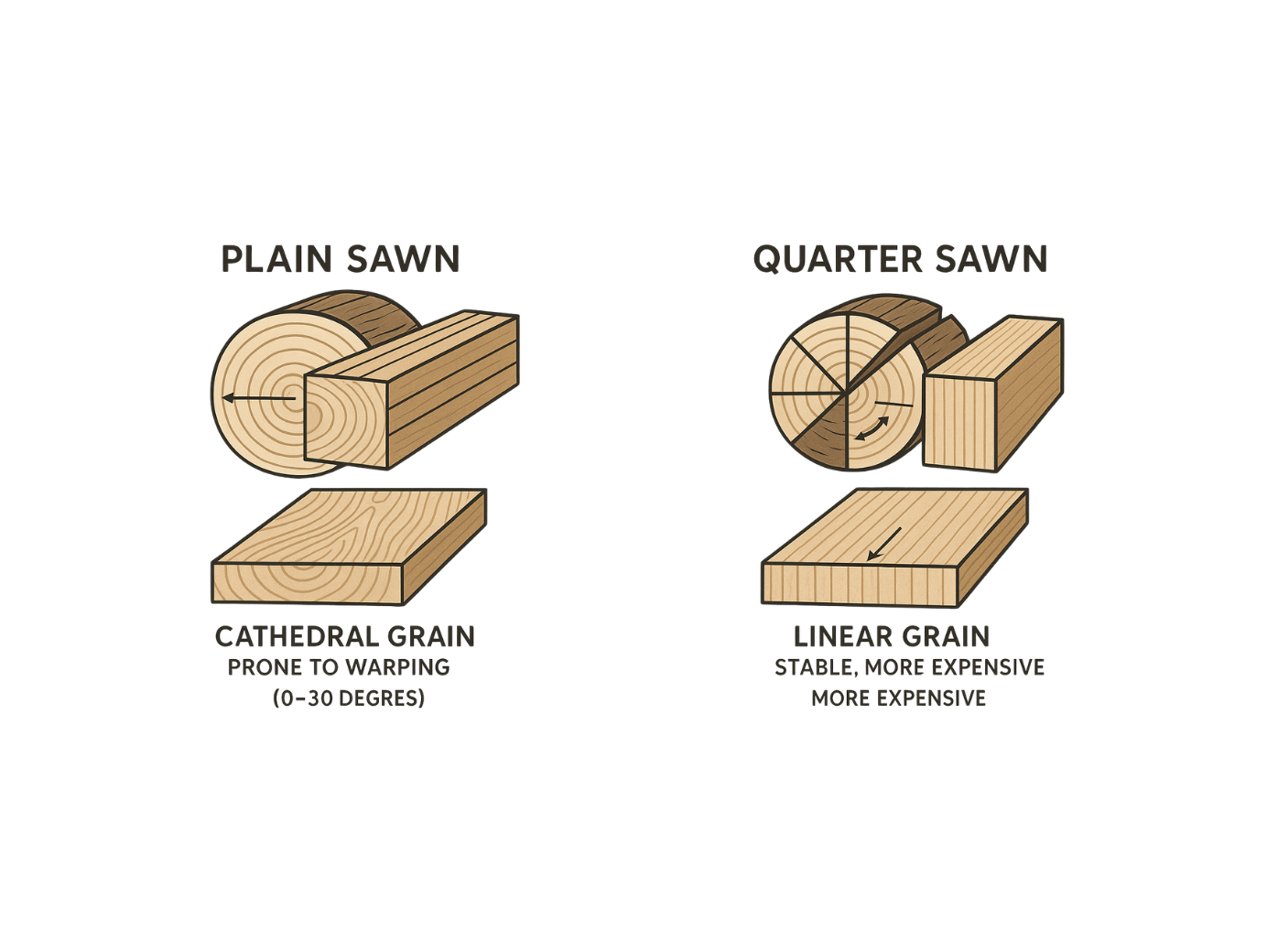

Plain sawing is the most common and economical method. Boards are cut straight across the log, producing a cathedral grain pattern with growth rings angled 0–30 degrees to the face. While it maximizes yield and minimizes waste, plain sawn lumber is prone to warping, cupping, and surface checking.

By comparison, quarter sawing produces a consistent linear grain pattern with growth rings oriented at 60–90 degrees. This makes the wood stronger, more stable, and more resistant to distortion. However, quarter sawing requires more labor and produces more waste than plain sawing, which is why the boards are generally more expensive.

For many high-end applications like furniture, flooring, cabinetry, the increased cost is justified by the performance and aesthetics of quarter sawn boards.

Quarter Sawn vs Rift Sawn Lumber

Quarter sawn and rift sawn lumber are often confused. Both involve cutting the log at angles that expose the wood's structure in unique ways.

Quarter sawn: Boards cut radially, producing straight grain and decorative ray fleck in species like white oak.

Rift sawn: Boards cut at a consistent 30–60 degree angle to the growth rings, creating the most uniform vertical grain with no fleck. Rift sawing is even more wasteful and expensive, but yields lumber prized for its precision and stability in architectural trim and minimalist furniture.

In practice, a project may use a mix of quarter sawn and rift sawn boards, depending on whether aesthetics (ray fleck) or uniform grain (rift) is the priority.

Working with White Oak

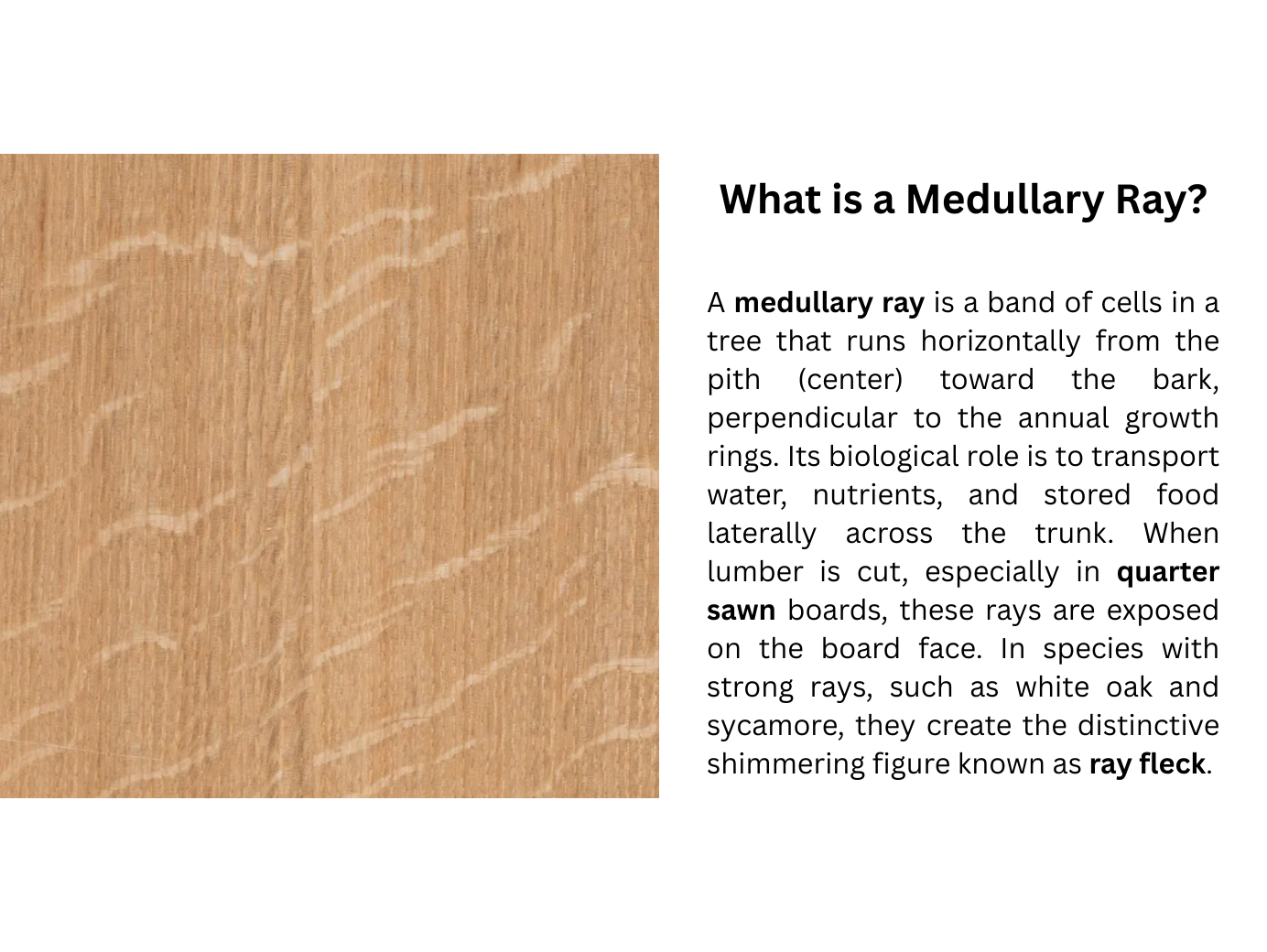

White oak is the benchmark species for quarter sawn lumber. Its strong medullary rays create the distinctive ray fleck pattern when exposed by quarter sawing. This shimmering figure, combined with the stability of the cut, makes quarter sawn white oak a staple in Arts and Crafts furniture, fine cabinetry, and premium flooring.

White oak is also naturally resistant to decay, making it highly recommended for applications requiring both strength and appearance. When paired with high-quality finishes, quarter sawn white oak boards highlight the contrast between the linear grain and the flecked figure, elevating both modern and traditional designs.

Compared to red oak, quarter sawn white oak is denser, stronger, and less porous, which enhances both its performance and lifespan.

Benefits and Advantages of Quarter Sawn Lumber

Dimensional Stability: Growth rings nearly perpendicular to the face resist cupping and surface checking.

Strength: Boards are structurally stronger than plain sawn, ideal for furniture and flooring.

Aesthetic Value: The linear grain pattern and ray fleck (in species like white oak) create a unique, decorative surface.

Durability: More resistant to wear, decay, and moisture absorption compared to flat sawn boards.

Versatility: Suitable for cabinetry, furniture, stair parts, flooring, and architectural millwork.

Compared to rift sawn lumber, quarter sawn is less wasteful while still providing high stability and strong visual appeal.

The William Ritter Lumber Company (operating from 1890 to 1960), known for its Appalachian oak flooring, developed a modified quarter sawing process to improve efficiency and reduce waste. Instead of fully quartering the log, the method began by removing the bark and several boards from two opposite faces. The log was then halved or in some cases divided into four parts, and each section was laid flat before being sawn at radial angles to produce quarter sawn boards.

Cost and Efficiency Considerations: Quarter Sawn Price Insights

Current Market Pricing (US, per board foot)

| Lumber Type / Thickness | Typical Price Range (USD) |

|---|---|

| 4/4 White Oak, Flat Sawn (plain) | $6.25 to $9.25 / bd.ft (bulk: $5.75–$9.85) |

| 4/4 Quarter Sawn White Oak | $9.95 to $16.35 / bd.ft depending on volume |

| 5/4 Quarter Sawn White Oak (S2S) | $12.80 to $14.20 / bd.ft |

| 8/4 Quarter Sawn White Oak | $12.85 to $17.85 / bd.ft |

| 4/4 Quarter Sawn White Oak | $14.99 / bd.ft (1–99 bf) $11.24+ / bd.ft (100+ bf) |

| Bulk (Rough, 13/16″ S2S) | $9.40 / bd.ft |

Cost Comparison

Plain (Flat) Sawn White Oak: Typical retail pricing ranges from $6 to $9 per board foot, with larger volumes dropping into the $5–$7 / bd.ft range.

Quarter Sawn White Oak: Retail pricing starts around $10 / bd.ft for modest quantities and goes up to $16–$18 / bd.ft for thicker or highly graded boards like 8/4 Select & Better. Bulk pricing (large orders or rough stock) may be closer to $9–$12 / bd.ft.

Efficiency Analysis

Quarter sawing generates more waste and yields narrower boards than flat sawing. However, compared to rift sawing, quarter sawing strikes a better balance, offering improved stability with moderately lower yield loss. Rift sawn boards cost more (often $16–$22 / bd.ft for white oak) due to highest waste and labor.

Value Proposition

Stability & Reduced Callbacks: Quarter sawn boards resist movement, cupping, and surface checking. Projects using quarter sawn white oak can save long-term costs associated with warping or replacement.

Wear Resistance for Flooring: The tight straight grain of quarter sawn boards, especially in white oak, provides enhanced abrasion resistance, justifying higher upfront material costs.

Aesthetic & Structural Return: For fine furniture and architectural millwork, the unique appearance (ray fleck, straight grain) and performance can command market premiums that offset the additional $5–$10 per board foot.

Example Calculation

If flat sawn white oak is $7 / bd.ft and quarter sawn is $12 / bd.ft, using 200 bd.ft in a project:

Flat sawn cost = $1,400

Quarter sawn cost = $2,400

Difference = $1,000 additional material cost

But if quarter sawn lumber reduces waste issues by even 10–15% and avoids a warp-related replacement, the extra cost is quickly justified in high-value or long-lifespan projects such as flooring or custom cabinets.

Common Applications

Furniture: Quarter sawn lumber is highly valued for fine furniture pieces where stability and appearance are critical. For example, Mission-style oak dining tables often showcase the ray fleck of quarter sawn white oak, while upright pianos use it for both structural stability and decorative effect.

Flooring: Quarter sawn white oak is a standard in premium hardwood flooring, particularly in historic restorations and high-traffic areas. Its straight grain resists wear and cupping, while the fleck pattern adds visual depth, commonly seen in Arts and Crafts homes.

Millwork: The cut is widely used for stair treads and risers, where dimensional stability prevents gaps and movement over time. It’s also selected for custom cabinetry doors, where the grain and fleck provide both strength and a distinctive look.

Architectural Work: In high-end interiors, quarter sawn lumber is used for wall paneling in libraries and boardrooms, where the combination of linear grain and ray fleck elevates the visual impact. It is also specified for church pews and altar woodwork, where both durability and decorative character are required.

Choosing Quarter Sawn Lumber for Lasting Value

Quarter sawn lumber is a technical solution to a timeless problem: how to create boards that resist warping while offering unique visual appeal. Quarter sawn lumber is produced by cutting a log into four sections and sawing boards at radial angles, typically 60–90 degrees to the growth rings. This orientation reduces tangential shrinkage, minimizes cupping, and increases dimensional stability compared to plain sawn boards. In species such as white oak, the process exposes medullary rays, creating the characteristic ray fleck figure.

Although quarter sawing yields narrower boards and generates more waste than flat sawing, the resulting lumber is stronger, more resistant to surface checking, and better suited for precision applications such as flooring, cabinetry, and architectural millwork.

Frequently Asked Questions

Related Articles

About CooperBuild Team

CooperBuild's in-house team brings expertise in custom millwork, lumber selection, and high-performance construction solutions for luxury projects in NYC.

Millwork & Construction Specialists

Subscribe to Our Newsletter

Get the latest insights, trends, and news from the construction industry delivered straight to your inbox.

We respect your privacy. Unsubscribe at any time.