Sawn Wood: Types, Cuts, and Uses Explained

Sawn wood cuts

Sawn wood is timber cut into boards or planks from logs. It is classified by the method of cutting (plain sawn, quarter sawn, rift sawn), the processing applied (rough-sawn, planed, kiln-dried, air-dried), and the grading system. Plain sawn lumber is produced by slicing through the center of the log, which affects the grain pattern and yield. Each sawing method produces different types of lumber or wood products, each with unique grain orientation, stability, and cost implications, making it essential to understand for construction, millwork, and furniture projects.

What is Sawn Wood?

Sawn wood refers to lumber that has been cut from logs into boards, planks, or beams. Unlike engineered products such as plywood or MDF, sawn wood comes directly from the log, with the grain structure intact.

In construction – it is used for framing, flooring, and structural components.

In millwork – it becomes cabinetry, moldings, and interior trim.

In furniture – it provides the raw material for tables, shelving, and chairs.

Because its properties depend heavily on how it is cut, dried, and graded, sawn wood remains a foundation of architecture, design, and woodworking.

How Sawn Wood is Produced

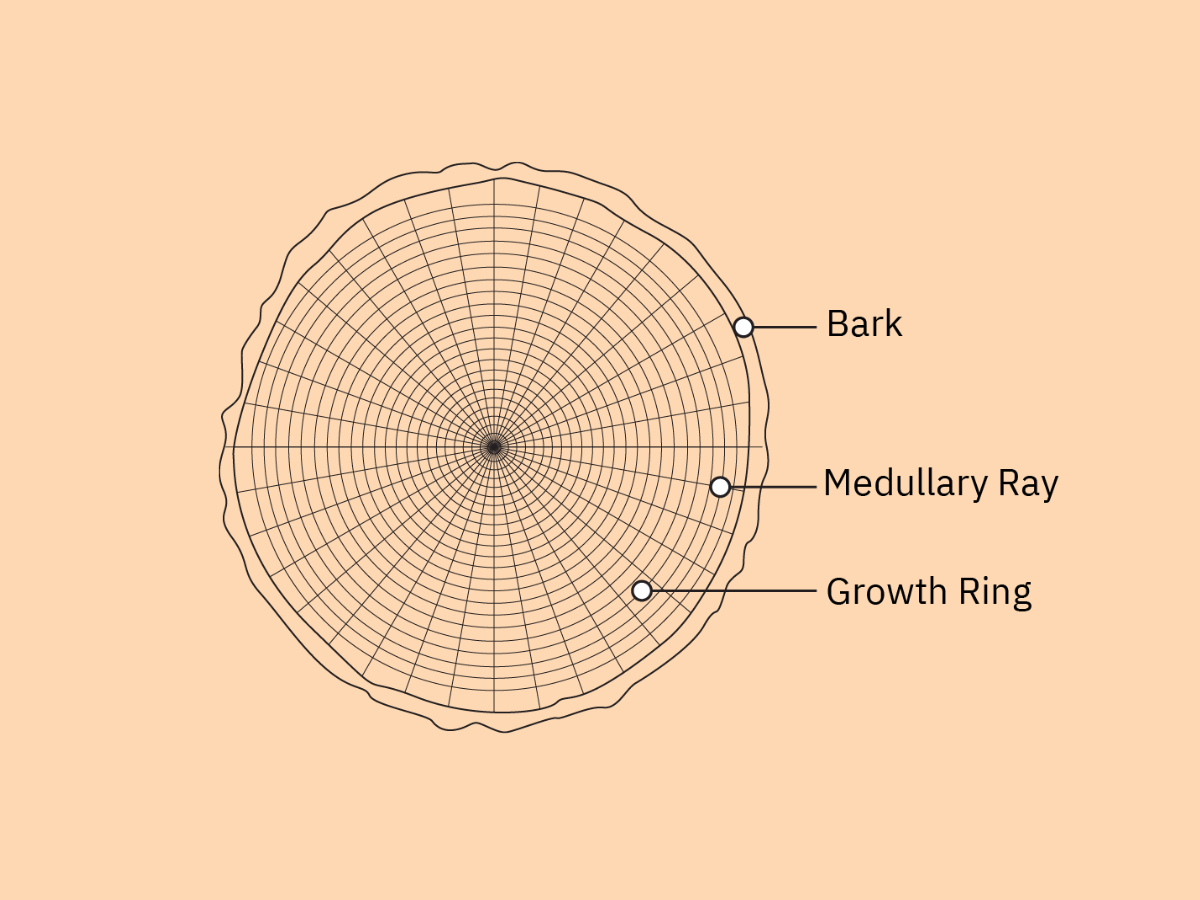

The process begins with debarked logs, cut into boards at sawmills. The chosen sawing method determines the grain orientation, yield, and waste.

The end grain of a board can reveal the method used to cut it, helping to distinguish between flat sawn, quarter sawn, and rift sawn boards.

Additional distinctions:

Rough-Sawn – boards straight from the saw with a textured face.

Planed – machined smooth, dimensionally accurate.

Moisture control follows:

Air-Dried – stacked outdoors; moisture varies.

Kiln-Dried – controlled drying; dimensionally stable, less risk of warp.

Types of Sawn Wood

A. Based on Cutting Method

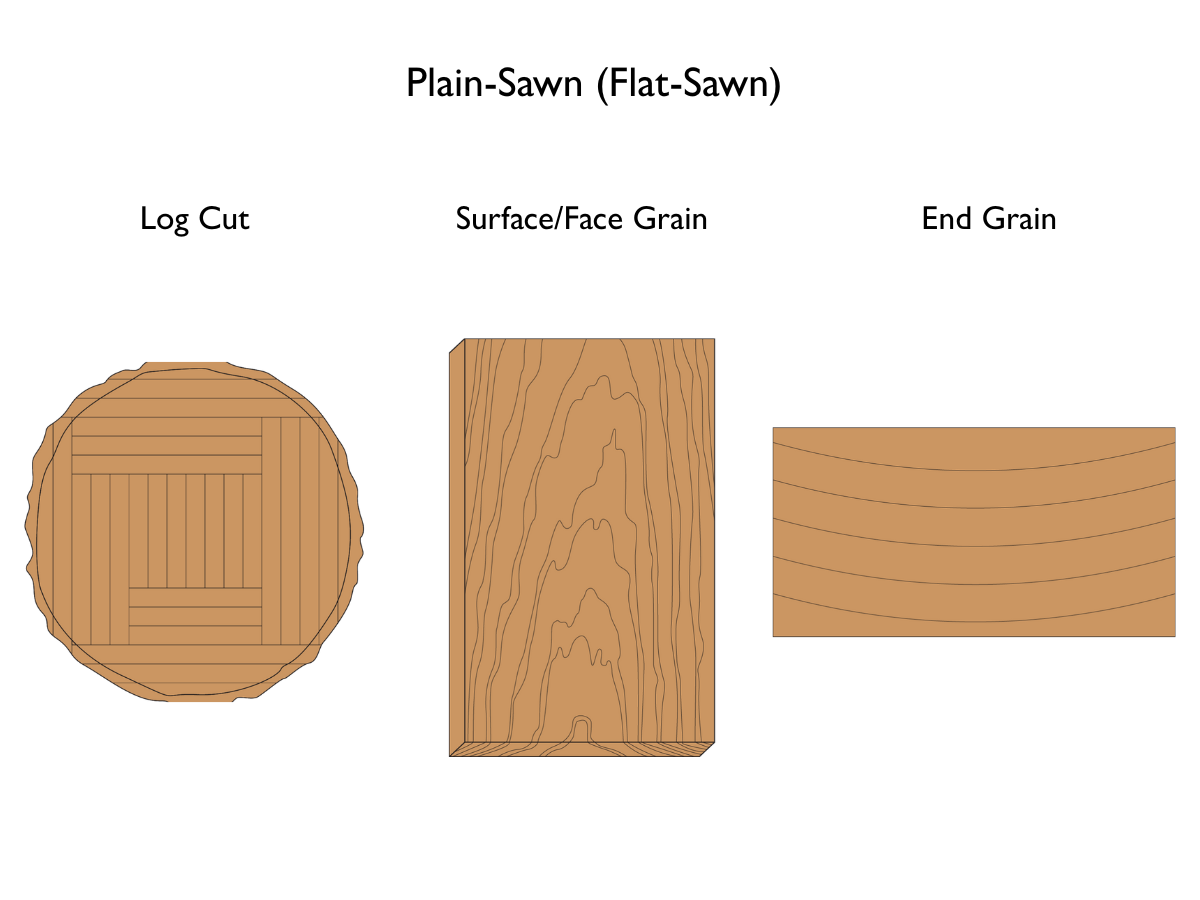

1. Plain-Sawn (Flat-Sawn) Lumber

plain sawn/flat sawn wood properties

Boards are cut tangential to the growth rings, with each subsequent cut made parallel to the previous one. The resulting lumber is known as flat sawn wood, which typically displays a wavy or cathedral grain pattern. Flat sawn wood is more prone to cup due to its grain orientation and is generally less stable, but it is the most economical method. The resulting lumber is widely used for its cost advantages and visual appeal.

- Most economical; maximizes yield.

- Shows cathedral grain patterns on the board face.

- Susceptible to tangential grain movement – more prone to warping.

- Used widely in framing, flooring, and economical furniture.

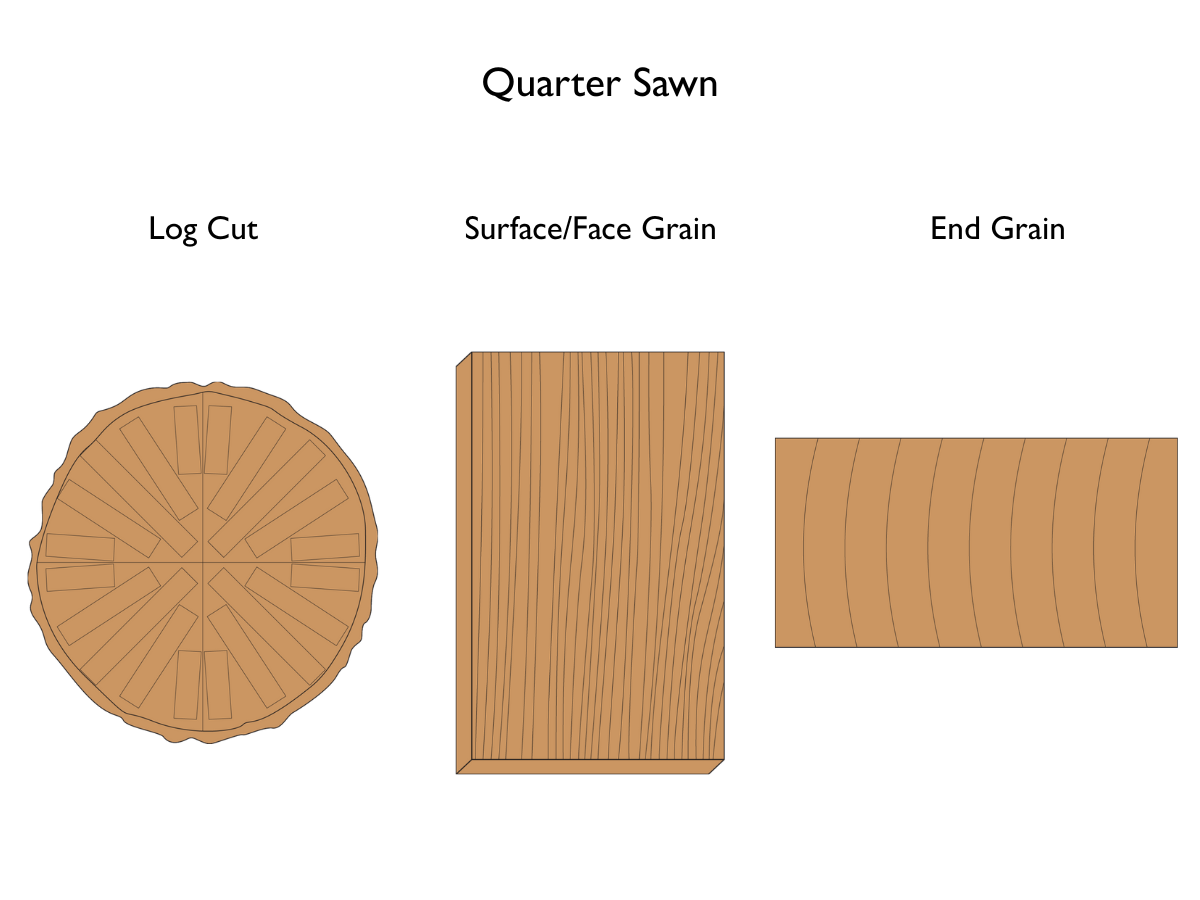

2. Quarter-Sawn Lumber

Quarter sawn lumber properties

Quarter sawn wood is produced by cutting a log into quarters, then sawing boards at perpendicular angles to the growth rings, resulting in lumber with superior dimensional stability and a unique, straight grain pattern.

This method produces straight, linear grain patterns and exposes the medullary rays, which appear as decorative ray fleck in species like white oak, enhancing the wood's aesthetic qualities.

- Quarter sawn wood is more dimensionally stable and less prone to cupping or warping compared to plain sawn lumber.

- It yields narrower boards and generates more waste, making it costlier.

- Quarter sawn wood is preferred in high-end furniture, cabinetry, flooring, millwork, and musical instruments due to its visual appeal and stability.

What is a ray fleck?

Quarter sawn oak showing ray fleck patterns

Ray fleck is the distinctive flake-like figure that appears on quarter sawn oak when medullary rays are cut across the board face. These rays are radial cell structures that run perpendicular to the growth rings, and when exposed, they create reflective, silvery patterns that contrast with the straight grain. Ray fleck is most visible in white oak and sycamore and is highly prized in fine furniture, cabinetry, and flooring for both its decorative quality and as proof of a true quarter sawn cut.

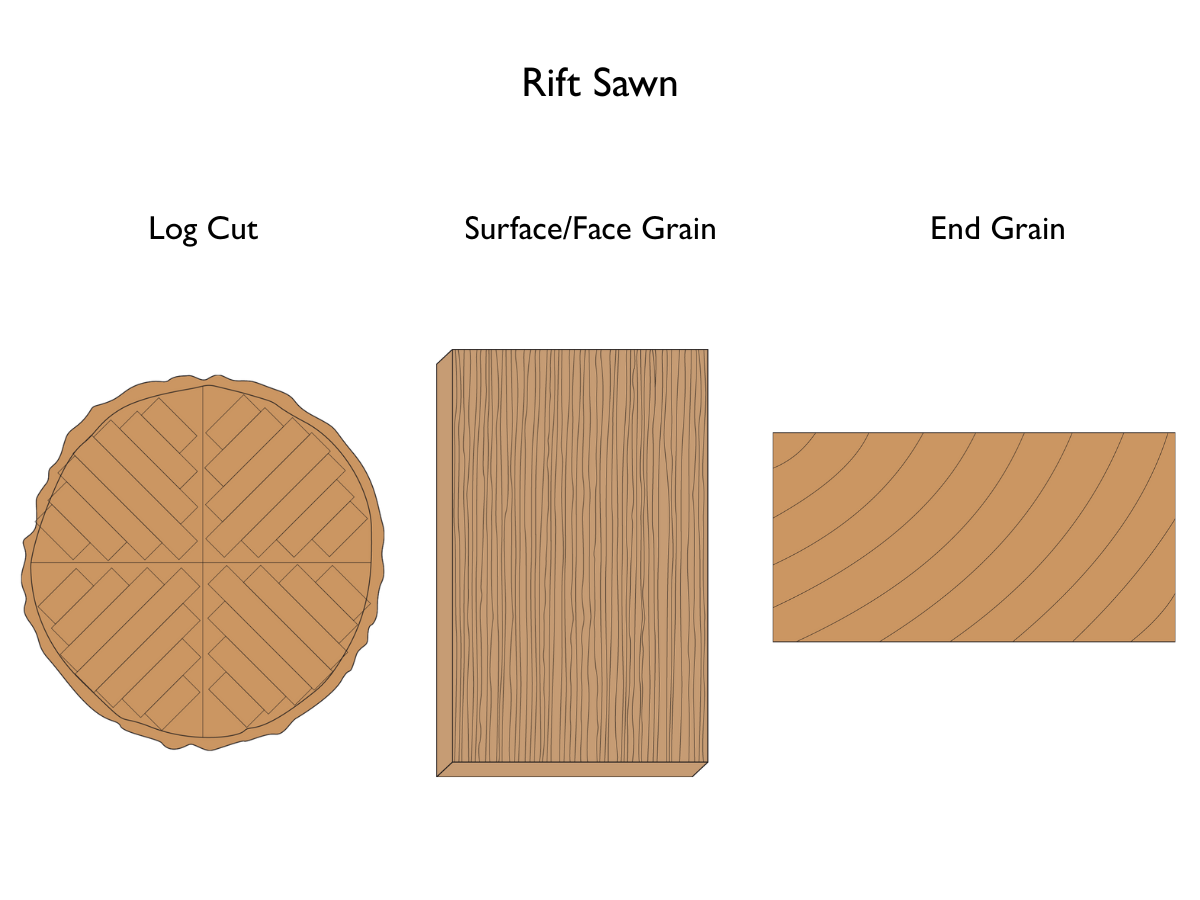

3. Rift-Sawn Lumber

rift sawn wood properties

- Rift sawing boards cut at consistent angles (30–60°) to growth rings.

- Creates the most uniform, vertical grain appearance.

- Extremely stable but produces the most waste; considered labor intensive.

- Typically used in high-end cabinetry, trim, and architectural detailing.

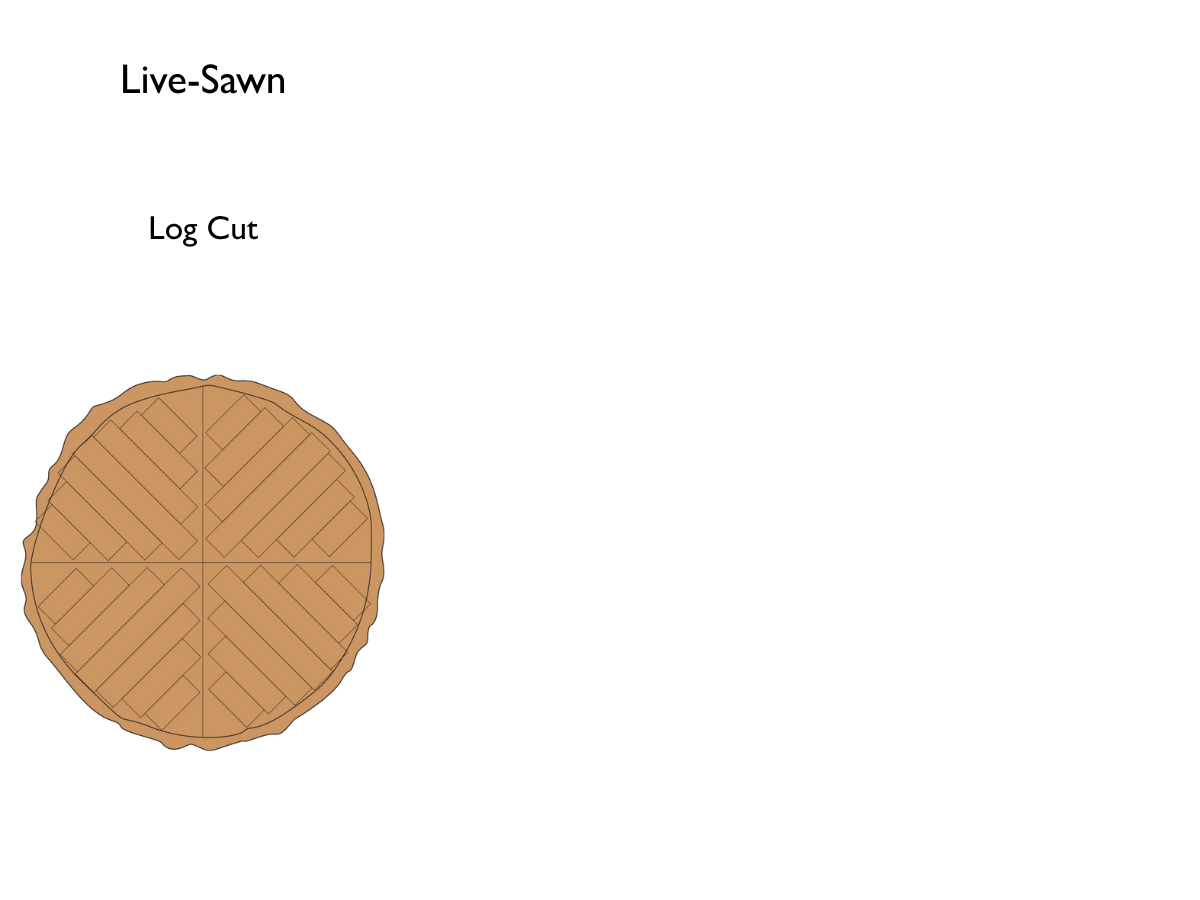

4. Live-Sawn Lumber

live sawn wood properties

- Boards cut straight across the log, combining plain, quarter, and rift cuts in one.

- Shows a wide variety of grain on the board face.

- Popular in European oak flooring.

B. Based on Processing & Seasoning

Rough-Sawn – no finishing, good for custom milling.

Planed (PAR – Planed All Round) – ready-to-use surfaces.

Kiln-Dried – stable, consistent moisture, prevents later warping.

Air-Dried – slower process, retains more natural color, but less predictable.

Measuring Sawn Wood

Accurate measurement is fundamental when working with sawn wood, as it directly impacts project planning, budgeting, and material selection. The standard unit for measuring lumber is the board foot, a volume measurement representing a piece of wood 12 inches long, 12 inches wide, and 1 inch thick. Calculating board feet allows you to determine how much material you need and to compare costs across different types of lumber.

When measuring quarter sawn lumber, it's important to account for its linear grain pattern and the fact that this method yields narrower boards due to the way the log is divided into quarters before cutting. This process is more labor intensive and produces more waste, which is reflected in the higher cost per board foot compared to plain sawn lumber. Plain sawn lumber, with its tangential grain pattern, is typically cut to maximize width and minimize waste, making it more economical but less dimensionally stable.

Rift sawn wood requires especially precise measurement, as the method produces the most waste and yields boards with a highly uniform, straight grain. Because rift sawn lumber is cut at a consistent angle to the growth rings, each board must be carefully measured to ensure optimal use of the log and to justify the higher cost associated with this premium product.

To calculate the total board feet for your project, multiply the width (in inches) by the length (in inches) by the thickness (in inches), then divide by 144. This calculation is essential whether you're selecting quarter sawn, plain sawn, or rift sawn boards, as it helps you estimate both the quantity of lumber required and the overall project cost. Understanding these measurements ensures you select the right type and amount of wood for your next project, while also managing waste and maximizing value.

Grading & Quality of Sawn Wood

Wood is graded either for strength or appearance:

Structural Grades – ensure load-bearing capacity (used in construction).

Appearance Grades – control defects, knots, and surface quality (used in millwork/furniture).

Hardwood vs Softwood Systems – hardwoods often appearance-graded (e.g., FAS in the U.S.), softwoods strength-graded.

Regional standards vary: the U.S. (NHLA for hardwoods), Europe (EN standards), and Asia each use distinct grading systems.

Applications of Sawn Wood

Construction – beams, studs, flooring, decking.

Custom Millwork – cabinetry, built-ins, paneling, trim.

Furniture – tables, chairs, shelving.

Architectural Uses – interior paneling, stair components, decorative details.

For example:

- Plain sawn red oak is common in flooring.

- Quarter sawn white oak highlights medullary rays in fine furniture.

- Rift sawn boards deliver uniform linear grain in minimalist cabinetry.

Advantages and Limitations of Sawn Wood

Advantages:

- Natural, renewable, strong.

- Wide species availability (oak, walnut, maple).

- Can be finished for both structural and aesthetic purposes.

Limitations:

- Sensitive to moisture (warp, shrink, expand).

- Cutting method impacts waste and cost.

- Requires finishing to resist wear and humidity.

Sawn Wood vs Engineered Wood

| Material | Strength & Stability | Cost | Best Use |

|---|---|---|---|

| Sawn Wood | Strong, depends on cut & drying | Varies (plain sawn = economical; rift/quarter = premium) | Millwork, furniture, architectural detail |

| Plywood | Very stable, layered | Moderate | Large panels, cabinetry, subflooring |

| MDF | Uniform, easy to machine | Low | Painted millwork, panels |

| LVL | Extremely stable | High | Structural beams, framing |

Choose sawn wood where appearance and natural grain matter; choose engineered alternatives for dimensional stability at scale.

Care & Maintenance

Storage – stack flat, with spacers, in climate-controlled areas.

Finishing – apply sealers, varnishes, or stains to protect from moisture.

Maintenance – re-oil or refinish surfaces exposed to wear.

Understanding how sawn wood is cut, graded, and processed helps architects, interior designers, millworkers, and homeowners select the right material for each application. From plain sawn lumber used in everyday construction to rift sawn wood chosen for precise, linear grain in high-end cabinetry, the method of milling defines both the performance and the cost of the final product.

Frequently Asked Questions

Related Articles

About CooperBuild Team

CooperBuild's in-house team brings expertise in custom millwork, lumber selection, and high-performance construction solutions for luxury projects in NYC.

Millwork & Construction Specialists

Subscribe to Our Newsletter

Get the latest insights, trends, and news from the construction industry delivered straight to your inbox.

We respect your privacy. Unsubscribe at any time.