Rift Sawn Wood: Understanding Its Benefits and Unique Characteristics

Rift sawn lumber cut properties

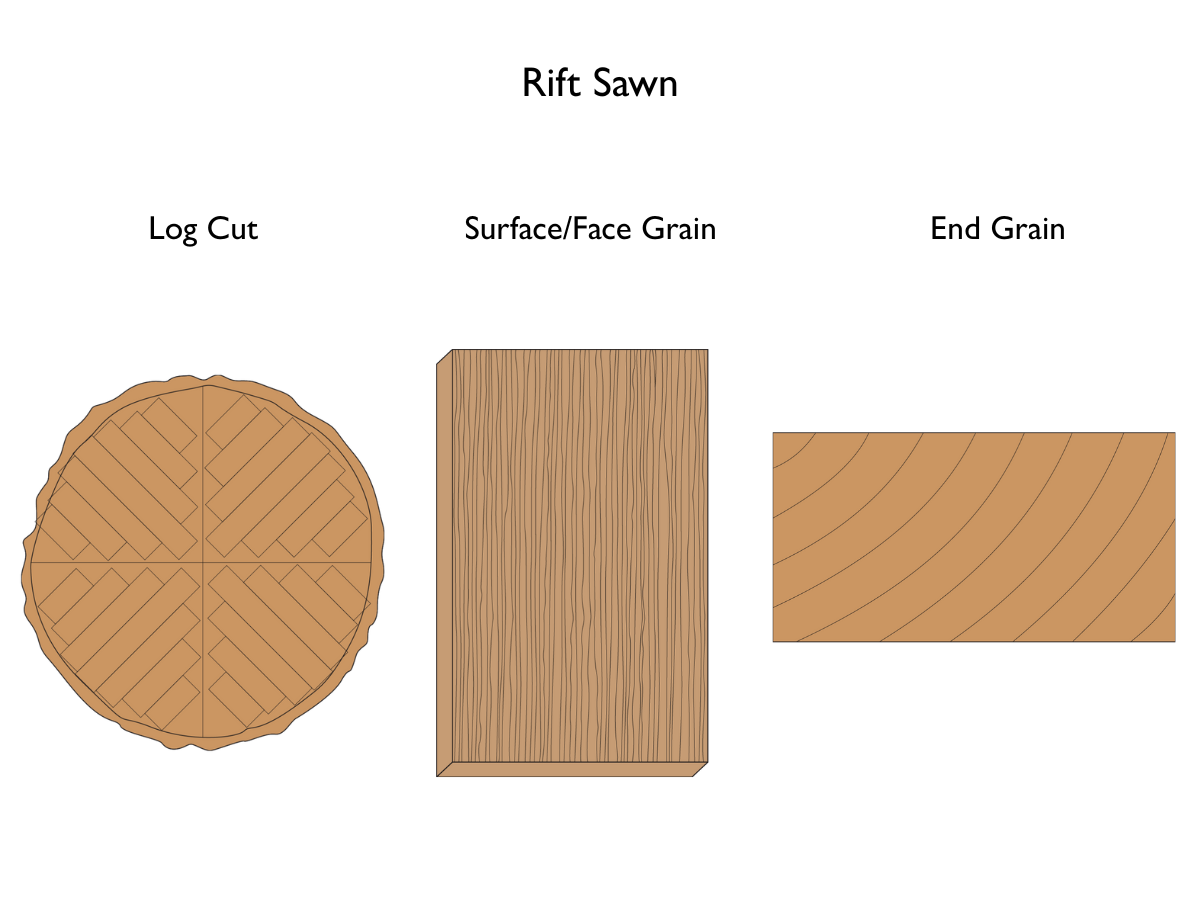

Rift sawn wood is a type of lumber cut where the growth rings intersect the face of the board at a 30°–60° angle, ideally around 45°. This produces a straight, linear grain pattern known as rift grain, with minimal ray fleck. It is cut radially, almost perpendicular to the growth rings, resulting in highly stable boards that resist warping, cupping, and splitting. It's commonly used in high-end furniture, cabinetry, and flooring where uniform grain and structural stability are essential.

There is often confusion among buyers and woodworkers regarding the differences between rift sawn and quarter sawn wood, largely due to imprecise diagrams and varied interpretations of cutting techniques.

Below is a guide for architects, interior designers, millworkers, and homeowners to really understand what "rift sawn" means, how it differs from other cuts (plain sawn, quarter sawn, live sawn), what its properties are, and when & how to specify or work with it.

What Does "Rift Sawn" Mean?

Definition & grain angle: In rift sawing, the growth rings of the log are cut at an angle of about 30° to 60° relative to the face of the board; 45° is the commonly referenced "optimum" angle for a true rift sawn appearance. Rift sawn boards are cut radially from the log, and the grain runs nearly parallel to the board edges. The direction of the grain in rift sawn lumber contributes to its dimensional stability, resulting in highly stable boards.

Grain pattern: "rift grain": The term "rift grain" refers to the linear, straight grain appearance, with minimal or subdued "ray fleck" (medullary rays' figure) compared to quarter sawn oak. Planks produced by rift sawing have a uniform appearance, and the surface of rift sawn lumber is smooth and consistent, making it desirable for fine applications.

Distinction from quarter sawn and plain sawn:

Plain sawn (flat sawn): Growth rings are shallow to the face (often < 30°), giving cathedral or flame-shaped grain patterns; this cut minimizes waste and is the most common lumber or common lumber type due to its high yield and affordability.

Quarter sawn: Log is first quartered, cuts tend toward perpendicular to the face (around 60°–90°), producing distinct straight grain and strong visible medullary rays or "fleck," especially in oak. The process required to produce quarter sawn boards is more involved and requires specialized know-how. Specific cutting techniques create the unique grain patterns and surface characteristics of quarter sawn lumber. Quartersawn white oak, in particular, is prized for its unique appearance and is often used in high-end furniture and cabinets.

Live sawn: All types of grain appear, because sawing is done without rotating or specially quartering; you get flatsawn, rift, and quartersawn patterns together.

Confusion often arises due to the similarities and differences between rift sawn and quarter sawn cuts, especially regarding grain direction and appearance. Different wood species and trees, with their unique growth patterns, also affect the final lumber characteristics. Medullary rays in oak can radiate from the center of the log like rays of the sun, adding to the visual interest of certain cuts. Rift sawn and quarter sawn lumber are commonly chosen for cabinets and fine woodworking due to their stability and attractive surface qualities. Producing these cuts requires know-how to ensure the desired grain direction and to create stable, high-quality boards.

Key Technical Properties of Rift Sawn Wood

Growth Rings & Grain Angle

The annular growth rings refer to the concentric rings in the cross-section of the log. The angle they make to the face of the board is what distinguishes plain, quarter, and rift cuts.

For rift sawing, aim for ~45°, but acceptable range is 30–60°, depending on how strict the definition is.

Medullary Rays & Ray Fleck

Medullary (or pith) rays are radial (from center outward) structures in wood that transport nutrients. These rays radiate from the center of the log like rays of the sun, creating a striking visual effect. In certain species (particularly white oak, red oak), they are large and visible as ray fleck when the board is cut nearly perpendicular to them.

In rift sawn wood, medullary rays are much less prominent or visible (depending on angle), since the face of the board doesn't intersect the rays in as dramatic a manner as quarter sawn.

End Grain and Face Grain Stability

With rift and quarter sawn lumber, the end grain tends to be more perpendicular to the face, which improves stability (less movement across width when moisture changes). Rift sawn lumber, in particular, produces highly stable boards with minimal movement, making it ideal for applications where dimensional consistency is critical.

Face grain is more consistent with rift sawn: straight, linear, fewer curves or large arcs ("cathedral" patterns) that you see in flatsawn.

Species Matters: White Oak, Red Oak, Maple, Cherry

White oak ("Quercus alba"): prized for pronounced medullary rays; excellent for quartersawn and rift sawn uses; non‑porous with tyloses makes it more stable. Quartersawn white oak is especially valued for its unique grain pattern, enhanced surface appearance, and superior stability, making it a popular choice for custom cabinetry and paneling.

Red oak: similar straight grain when sawn properly; ray fleck less dramatic than white oak, but visible. Good variant when white oak is cost prohibitive.

Maple, Cherry, Walnut, etc.: these wood species have very small medullary rays; grain pattern differences are subtler; rift / quarter sawn chiefly valued for straightness, stability rather than decorative ray figure. Different wood species are chosen for their unique grain patterns, stability, and suitability for specific applications.

How Rift Sawing Is Performed (The Process)

Log selection

Start with a log that is relatively straight and without defects. Larger diameter helps but increases complexity.

Quartering the log

Many rift and quarter sawing methods begin by splitting the log into quarters—this helps orient the cuts properly.

Sawing angles

With each quarter, boards are cut radially at the target angle (≈ 30‑60°) to growth rings. This process creates the unique straight grain pattern and structural characteristics that rift sawn lumber is known for. Sometimes the log is rotated between cuts to maintain appropriate angle. Rift sawn boards are specifically cut radially from the log to achieve the desired grain orientation and stable boards. Specialized know-how is required to properly perform rift sawing and ensure the quality of the final plank.

Optimizing for yield vs visual uniformity

To get cleaner straight grain and uniform edge-to-face appearance, the sawyer may accept more waste (wedge‑shaped offcuts).

For cost control, some cuts are approximate; wider boards may show transition of grain across width (some parts more slanted).

Drying / Seasoning

Rift/quarter sawn wood must be properly dried to avoid surprises. Even with ideal cuts, moisture content changes will cause movement; but woods cut this way perform much better under fluctuating humidity.

Current U.S. Market Prices for Rift Sawn Lumber (Per Board Foot)

| Species / Cut / Thickness / Context | Approx Price / bd ft (USD) | Notes / Conditions |

|---|---|---|

| White Oak, Rift Sawn (4/4), S2S / surfaced | ~$16.99 / bd ft | Woodworkers Source offers Rift Sawn White Oak 4/4, surfaced both sides, widths 4‑6", lengths 6‑12 ft. |

| White Oak, Rift Sawn (4/4), smaller surfaced stock | ~$11.50 / bd ft | Wood Flippers: S3S milling; this is lower quantity / smaller widths or less premium grade. |

| White Oak, Rift or Quarter & Rift, higher volume (100‑249 bd ft) | ~$16.35 / bd ft | From Wood Vendors, for 4/4 or 5/4 white oak rift or quarter/rift, for moderate volume purchases. |

| White Oak, Rift or Quarter & Rift, larger volume (1000+ bd ft) | ~$12.10 / bd ft | Same source (Wood Vendors), reflects bulk pricing with considerable volume discount. |

| Red Oak, Reds (Rift or Quarter & Rift), 4/4 | ~$7.90 / bd ft (for moderate quantity) | Wood Vendors publishes this for 100‑249 board feet. |

| Red Oak, Rift / Quarter & Rift, large quantity (1000+ bf) | ~$4.40 / bd ft | Again Wood Vendors; large quantity discount markedly lowers the unit cost. |

| Red Oak, Rift Sawn 5/4 | ~$5.00 / bd ft | Alexander Bros' asking price for Rift Sawn Red Oak at 5/4 thickness. |

When & Where to Use Rift Sawn Lumber

Best application contexts:

Furniture design: pieces where all visible surfaces (face, edges) are exposed and you want a uniform appearance, straight lines — e.g. table aprons, rails, legs.

Cabinetry / Millwork: particularly for face frames, vertical panels, shelving, and cabinets where minimal distortion, enhanced stability, and clean grain lines matter. Rift sawn and quarter sawn lumber are often chosen for cabinets to improve both stability and aesthetics.

Flooring: high‑end hardwood flooring in humid climates; long narrow boards. Rift sawn white oak flooring is a premium product.

Architectural elements: stair treads, handrails, mouldings, trim—places where edges are exposed and straight grain looks more refined.

Design styles: modern, minimalist, Scandinavian, Japanese or Mid‑Century work where linear grain enhances the aesthetic.

When rift sawn may not be ideal:

- Projects where cost / budget is constrained.

- Wide planks where you want pronounced decorative figure (ray fleck), plainsawn or quarter sawn may give stronger visual impact.

- Species which do not show medullary rays much; investing in rift may not give sufficient visual return.

How to Specify Rift Sawn (What to Ask For)

- Specify grain angle: ask for growth rings intersecting board face at 30°–60°; if possible, around 45°.

- Clarify medullary ray figure: do you want minimal ray fleck (rifty look) or are you okay with more fleck (quarter style)?

- Species: white oak, red oak are the most commonly used; understand their ray properties.

- Board widths and lengths: expect narrower widths for pure rift sawn; wider boards may show edge‑to‑centre grain variation.

- Grade: higher grades often offer clearer wood, fewer defects; rift sawn tends to cost more, both in sawmilling and grading.

- Moisture content / drying specs: important especially in humid climates.

- Finish / stain testing: straight grain rift sawn may absorb stain differently vs quarter or plain; subtle difference in appearance under stain.

Practical Tips for Working with Rift Sawn Lumber

- Check end grain samples before ordering large quantities; angle of growth rings is visible in end grain.

- For staining / finishing: test samples, since stain tends to highlight grain and rays differently (pigment vs dye stains behave differently).

- Mind joinery behavior: less movement across width, so joints (especially wide panels) are more reliable.

- Plan layout: rift sawn boards tend to have more consistent color / fewer dramatic grain changes, so visual matching is easier.

- Handling waste: since rift produces more scrap offcuts, cost of waste (or possibility to use scrap for smaller parts) should be factored in.

Common Misconceptions & Clarifications on Rift Sawn Woods

Confusion often arises among buyers and woodworkers regarding the differences between rift sawn and quarter sawn wood, leading to several common misconceptions.

"Rift sawn = no ray fleck" — Not always. Some ray can still appear in rift sawn, depending on species, angle, and board width. But it will generally be less prominent than in quarter sawn.

All boards from a rift sawn log are identical — Rarely. Even in rift cuts, edges or wide boards may show variation; straightness can drift depending on angle consistency.

Wider boards = rift sawn — Usually the reverse; true rift boards tend to be narrower because of how waste increases with width.

Plain sawn lumber = bad — Plain sawn has its place: lower cost, dramatic grain, wider boards; for many applications (trim, design features, budget flooring) plain sawn works quite well.

Summary: When Rift Sawn Is the Appropriate Choice

- When visual consistency and straight grain on all exposed faces are priorities.

- When structural stability / long‑term dimensional stability are required (furniture, flooring, cabinetry in humid/hot environments).

- When the design aesthetic is clean, modern, linear, minimal grain variation.

- When budget allows for higher cost and more waste, or when cost is justified by longevity & performance.

Frequently Asked Questions

Rift sawn wood is a type of lumber cut where the growth rings intersect the face of the board at a 30°–60° angle, ideally around 45°. This cutting method creates a straight, linear grain pattern, known as rift grain, with minimal ray fleck. The grain runs nearly parallel to the board's edges, giving a clean, consistent appearance on all sides.

Yes. Rift sawn lumber exhibits much more predictable shrinkage/swelling behavior, especially across its width, because the grain is more radial. This helps reduce warping, cupping, and twist. Plain sawn will swell/shrink more across the width and show more irregularity.

It depends on species, log size, and grades, but expect significantly higher cost. The extra cost comes from greater waste (wedge offcuts), slower milling, and narrower boards. Quarter sawn is already more expensive than plain; rift is usually even more.

In quarter sawn white oak, rays are usually very visible—they produce distinctive flake patterns when intersected near perpendicular. In rift sawn, they are much less prominent—often subtle or nearly invisible depending on exact angle and width.

Yes, but with caveats. Wider boards increase the chance that parts of the board have drifted grain angle (toward quarter or even flatsawn behavior), and larger boards mean more waste. Also, achieving perfect rift angle across full width is more challenging.

Sometimes. If your design demands clean linear grain on all visible surfaces, edges, and a uniform look, yes. But quarter sawn (or even carefully selected plain sawn) may suffice in many cases where performance is less critical. It becomes a balancing act between aesthetics, budget, and long‑term behavior.

It depends on your priorities. Rift sawn wood offers a more uniform, straight grain on all visible faces and greater dimensional stability, making it ideal for modern furniture, clean-line cabinetry, and flooring. Quarter sawn wood, on the other hand, shows more decorative ray fleck (especially in white oak) and provides excellent stability, though slightly less uniformity in edge grain. So:

Choose rift sawn for: clean aesthetics and uniform grain.

Choose quarter sawn for: visual interest (fleck) and strength in larger boards.

While rift sawn lumber has many advantages, including superior stability and clean aesthetics, it comes with a few drawbacks:

Higher cost: Due to the extra labor and lower yield (more waste during milling), it's significantly more expensive.

Limited widths: Boards tend to be narrower; wide rift sawn boards are rare and costly.

Less figure: Lacks the decorative medullary ray "fleck" you get from quarter sawn wood (especially in oak).

Availability: Not all species are easily sourced in true rift sawn cuts, and availability may be limited depending on region.

Plain sawn (flat sawn) doors typically show cathedral or arched grain patterns on the face, with less consistent grain on edges and sides. These doors are more prone to cupping or twisting due to tangential grain alignment.

Rift sawn doors, in contrast, exhibit a very consistent, straight grain across all visible surfaces (face, edge, stiles), giving them a more refined and modern appearance. They also tend to be more stable over time—resisting warping, bowing, or twisting. However, they cost more and may have less visual "movement" in the grain.

Related Articles

Subscribe to Our Newsletter

Get the latest insights, trends, and news from the construction industry delivered straight to your inbox.

We respect your privacy. Unsubscribe at any time.