Metal Stud Framing: Load-Bearing vs Non-Load-Bearing Walls & Installation Guide

Metal stud framing system installation for commercial construction

Metal stud framing is a non-combustible wall and ceiling framing system that uses cold, formed galvanized steel components, typically C-shaped studs and U-shaped tracks, to construct structural and non-structural assemblies. It replaces traditional wood framing in commercial, institutional, and multifamily buildings where fire ratings, dimensional stability, and resistance to moisture, rot, and insects are critical. Studs are sized and spaced according to load requirements, wall height, and finish specifications, and are fastened using self-drilling screws or mechanical anchors.

What Is Metal Stud Framing?

Metal stud framing is a construction system that uses cold-formed steel components, primarily C-shaped studs and U-shaped tracks to frame walls, partitions, soffits, and ceilings. These components form the structural "skeleton" to which drywall, finishes, and systems like plumbing and electrical are attached.

In other words, it's the steel version of the wood 2×4 system.

Metal studs provide a stronger alternative to wood studs, which can split and shrink over time. But unlike wood, metal studs don't rot, warp, shrink, or invite termites. They're straight, lightweight, and manufactured to tight tolerances, making layout and coordination far easier for both architects and field teams.

Metal Stud Framing in 2026 Construction

In 2026, metal stud framing is widely considered the gold standard for commercial and high-performance residential construction. Metal stud framing has become a go-to solution for architects, designers, and contractors looking for strength, consistency, and fire resistance in both residential and commercial construction. As energy codes tighten and durability expectations rise, traditional wood framing faces more scrutiny, especially in multifamily, industrial, and high-performance buildings.

You've probably already seen specs calling for metal studs in everything from tenant fit-outs to ceiling systems. But when exactly should you use them? And how do they differ from wood? If you're a young architect, an interior designer drafting your first CD set, or a homeowner navigating renovations, understanding metal stud framing is essential.

This article breaks down everything you need to know, clearly, technically, and without the fluff. You'll leave with the knowledge to choose, specify, and build confidently using metal studs on your next project.

Why It's Used:

- Fire resistance: Metal won't burn, unlike wood framing.

- Lightweight systems: Ideal for high-rise, mezzanine, or ceiling partitions.

- Predictable behavior: No warping or twisting means better finish performance.

- Speed of installation: Prefabricated systems cut down on build time.

At a practical level, metal stud framing supports both load-bearing structural applications and non load bearing interior partitions, making it one of the most versatile tools in commercial and residential construction.

When to Choose Metal Over Wood Framing

Metal studs are often contrasted with wood studs, which have been traditionally employed in construction for centuries. Choosing between metal and wood framing is about performance, durability, and long-term value. Metal framing has a number of advantages over traditional wood framing, making it particularly well-suited to environments with moisture, gale force winds, and insects.

Metal is the better choice when:

- You're building in moisture-prone areas (basements, bathrooms, coastal environments).

- Non-combustibility is required by code (many multi-family and commercial projects).

- You need precision. Metal components don't change shape with humidity.

- Speed is critical. Metal studs can be pre-cut or prefabricated.

Wood still has its place:

- Lower material costs for single-family homes and small structures.

- Easier field modifications (anyone with a saw can trim wood studs).

- Thermal insulation properties. Wood performs better unless thermal breaks are used in steel systems.

Still, in urban commercial buildings, industrial construction, and anywhere fire rating is required, metal stud framing is often non-negotiable. It's lighter than wood, resists mold, and doesn't shrink, meaning fewer callbacks and more durable assemblies. Steel is also 100% recyclable, generating far less on-site waste compared to wood.

Types of Metal Studs: Know What You're Working With

Before you spec or install anything, you need to understand the types of metal studs available, and what each is designed to do. Not all studs are built for structural loads, and using the wrong one can create serious performance issues.

The Two Main Categories:

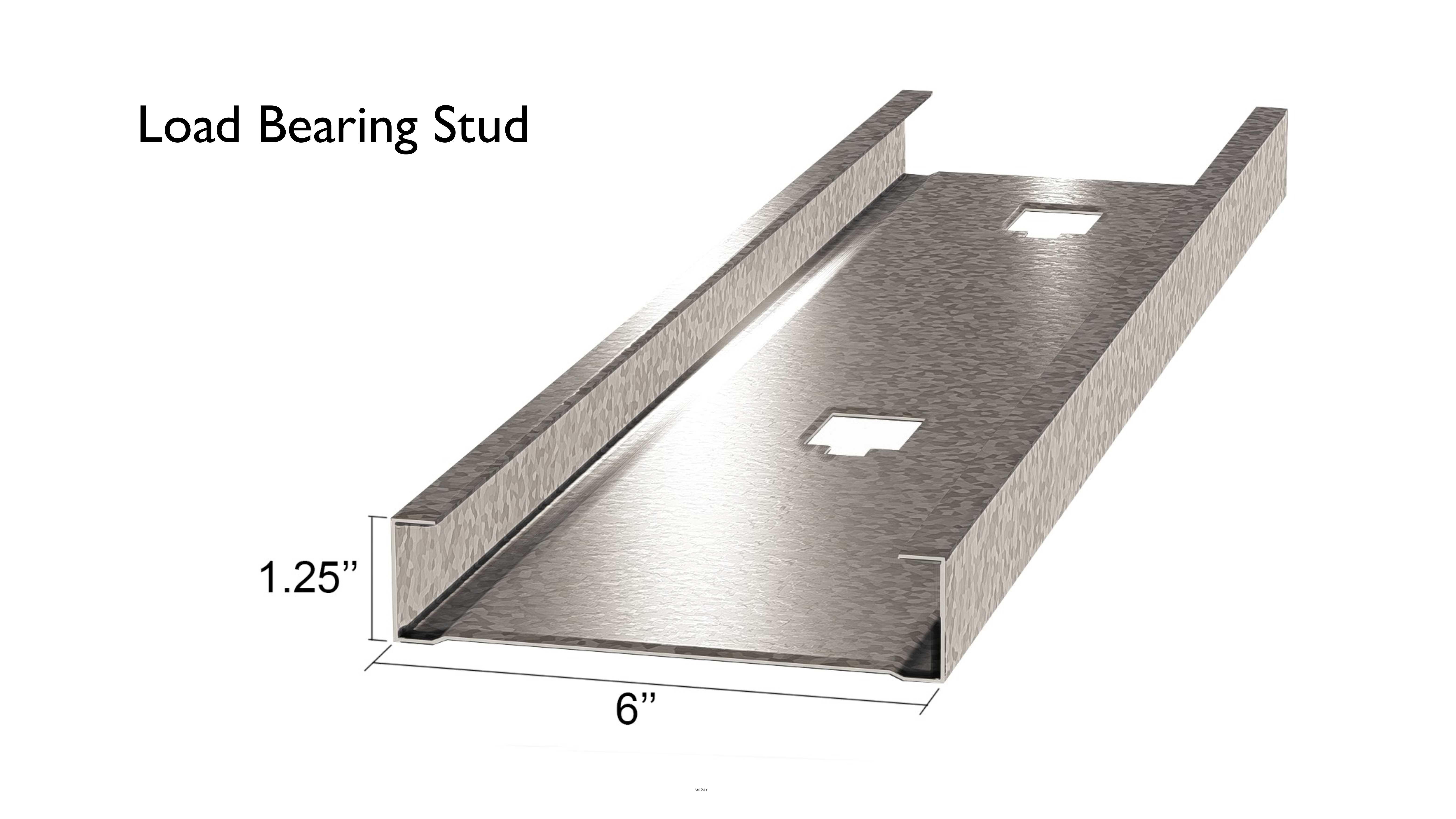

Load Bearing Studs

load bearing stud example

- Typically made from heavier gauge steel (16–20 gauge).

- Designed to carry structural loads from walls, floors, or roofs.

- Common in commercial, industrial construction, or multi-story residential buildings.

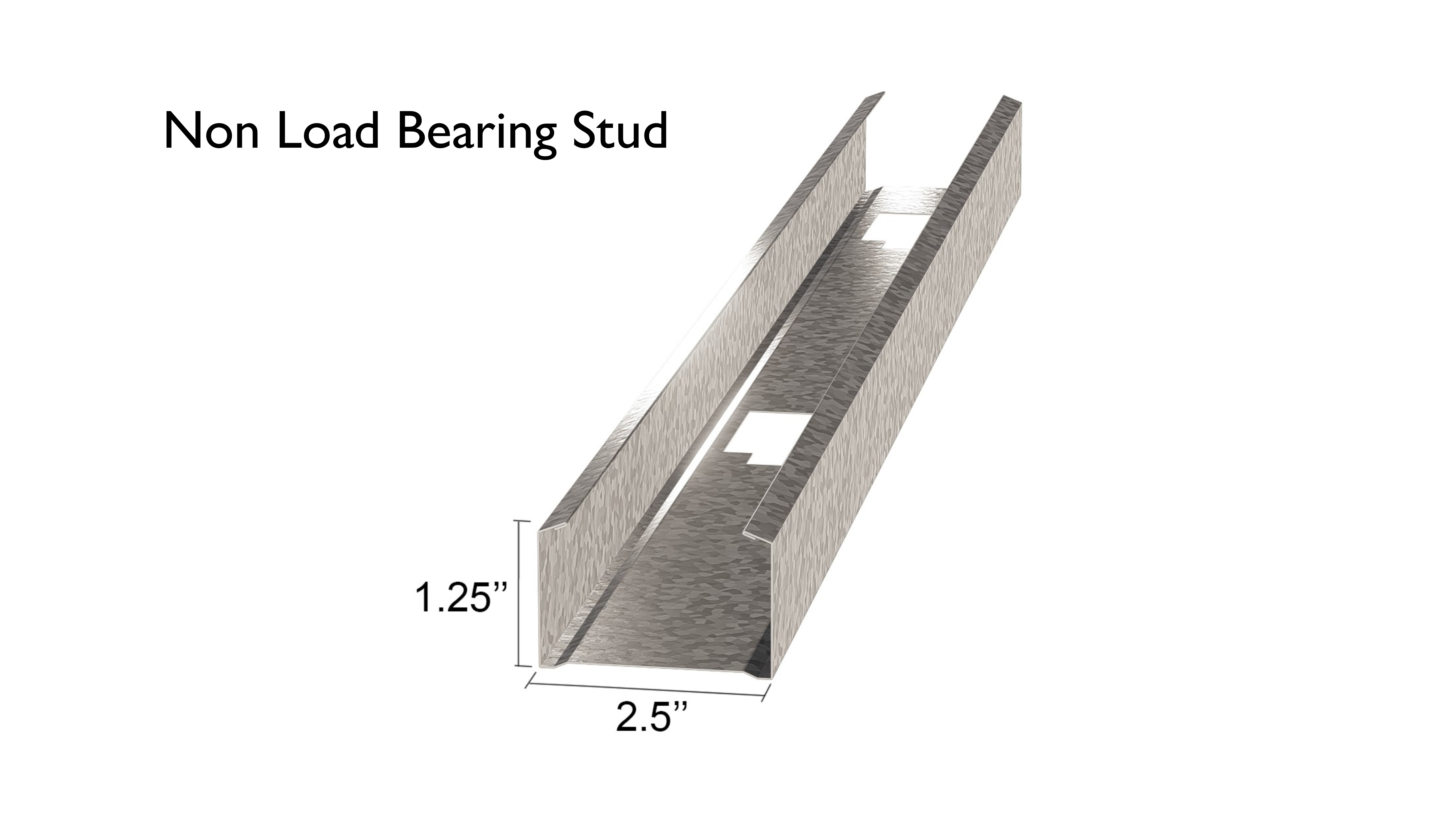

Non Load Bearing Studs

non load bearing stud example

- Lighter gauge (22–25 gauge), meant only to support interior finishes like drywall.

- Used in partitions, ceilings, bulkheads, and other non-structural locations.

In short: Don't use non-load-bearing studs to carry weight, and don't overspend by using structural studs where they're not needed. Understanding these categories lets you optimize both cost and performance on your project.

Load Bearing Walls: Structural Role of Metal Studs

In load bearing structural applications, metal studs must transfer vertical and lateral loads safely to the foundation. This includes supporting:

- Roof trusses or joists

- Floor systems above

- Lateral wind or seismic forces

Metal studs for load-bearing walls typically require:

- Thicker gauge steel (often 16 or 18 gauge)

- Double or boxed studs at critical points

- Proper bracing to resist twisting or buckling

You'll often find them in mid-rise buildings, light commercial structures, or mixed-use residential projects, especially when a fire-rated, moisture-resistant system is required.

Why It Matters:

Poorly designed load-bearing metal walls can fail under compression or lateral forces. To prevent this, engineers must calculate:

- Stud spacing (commonly 16" or 24" on center)

- Wall height vs. stud strength

- Load combinations (live, dead, wind, seismic)

Always coordinate closely with structural engineers and adhere to ICC and ASTM standards, especially when heavy loads are involved.

Non Load Bearing Applications: Flexibility in Interior Builds

Non-load-bearing metal studs make up the bulk of interior framing work. These studs aren't required to carry structural loads, so they're thinner, lighter, and cheaper, but still critical to the overall system.

Typical Non-Load Bearing Applications:

- Office partitions

- Retail fit-outs

- Residential basement walls

- Drop ceilings and soffits

- Chase walls (for plumbing, HVAC, etc.)

Designers love non-load-bearing studs for their versatility and speed. They install quickly, are fire-resistant, and don't warp like wood, making them ideal for drywall finishes, precise alignments, and modern interiors.

Important Considerations:

- Studs should still be properly braced to avoid twist or bowing, especially at tall heights.

- Always check with the manufacturer on height limitations based on gauge.

- Add horizontal bracing or bridging for better rigidity.

This system is especially useful in tenant improvement work, where walls might be moved or reconfigured without affecting structural elements.

Understanding Gauge: Why Steel Thickness Matters

If you take one technical lesson away from this post, make it this: Gauge equals strength.

In metal stud framing, gauge refers to the thickness of the steel, and it plays a critical role in:

- Load-carrying capacity

- Wall height limitations

- Fastening strength

Quick Reference:

| Gauge | Thickness (inches) | Use Case |

|---|---|---|

| 25 | 0.018" | Short partitions, drywall backing |

| 20 | 0.033" | Taller interior walls |

| 18 | 0.043" | Light structural framing |

| 16 | 0.054" | Load-bearing walls |

The lower the gauge, the thicker and stronger the steel. So if you're designing a wall over 10 feet tall, or one that will support weight (like upper cabinetry or doors), don't risk using 25-gauge studs. Upgrade to at least 20 or 18 gauge.

For load-bearing applications, always consult a structural engineer and use stamped calculations, guesswork won't cut it.

Track and Stud System: Core Components of Metal Framing

Metal stud framing relies on a simple but effective system: vertical studs slide into horizontal tracks at the top and bottom of the wall. Together, they create a lightweight, rigid skeleton for your walls or ceilings.

Key Parts of the System:

- Studs – C-shaped vertical members that carry loads or create partitions

- Track – U-shaped channels that hold studs at the floor and ceiling

- Bridging/Blocking – Horizontal reinforcements to stiffen tall walls

- Angle clips & connectors – Used to fasten frames to structure

This setup is modular, repeatable, and ideal for prefabrication. Crews can frame entire demising walls or office layouts in days, not weeks.

Pro Tip:

Install all track first, then insert studs one by one. Secure with self-tapping screws through the flange. For higher loads, use angle brackets or shot pins to anchor track to slab or deck.

How Metal Studs Go From Drawing to Wall

Whether you're the designer or GC, understanding the installation flow helps you plan, schedule, and coordinate better.

Here's How Metal Stud Framing Typically Progresses:

1. Layout Field team chalks layout lines based on architectural specifications and shop drawings.

2. Track Installation Tracks are installed at floor and ceiling lines using anchors or screws.

3. Stud Placement Studs are cut to height and inserted into track, 16" or 24" O.C.

4. Fastening Screws fasten studs to track. Additional blocking added where required.

5. Bracing For tall or load-bearing walls, bridging is added for lateral stability.

6. Inspections Framing is checked before mechanical rough-in and drywall.

7. Drywall Panels are hung, finished, and made ready for final finishes.

Knowing this process lets architects design smarter details, like coordination for MEP penetrations, blocking for millwork, or flush reveals in modern interiors.

Framing for Ceilings and Soffits: What Changes Overhead?

Ceiling framing with metal studs introduces a new set of rules.

Instead of vertical studs and floor-mounted track, you're dealing with horizontal framing systems often suspended from structure using hanger wire, angle brackets, or cold-rolled channels.

Systems Include:

- Hat channel framing for gypsum board ceilings

- Soffit framing with cold-formed angles and studs

- Suspended systems for acoustic or T-bar ceilings

Always Consider:

- Span limitations of framing members

- Integration with mechanical systems (HVAC, plumbing)

- Code requirements for fire-rated ceilings or chase construction

Field coordination is essential here. One missed duct offset can lead to major soffit rework.

Tools and Fasteners Required for Metal Framing

Installing metal studs requires different tools than wood and skipping the right equipment can cause weak joints or delays.

Must-Have Tools:

- Screw guns with clutch settings

- Aviation snips for cutting studs

- Chop saws or cold-cut saws for clean, square cuts

- Plumb lasers for layout accuracy

- Framing squares and levels

Fasteners:

- Self-drilling drywall screws for drywall to stud

- Framing screws (⅞" to 1¼") for stud-to-track connections

- Power actuated fasteners (PAFs) for concrete anchoring

- Toggle bolts or hollow wall anchors for mounting to finished walls

Invest in quality tools upfront, it speeds up your install and prevents errors later.

Common Errors in Metal Stud Framing and How to Avoid Them

Mistakes in metal stud framing can lead to cracked drywall, failed inspections, or expensive rework. Here are some common errors to watch for:

1. Wrong Gauge Selection

Using light-gauge studs in a tall or load-bearing wall can cause deflection, bowing, or even collapse.

2. Improper Fastening

Relying on drywall screws instead of structural framing screws results in weak connections.

3. No Lateral Bracing

Tall walls without bridging can twist or sway, especially before drywall is installed.

4. Missing Blocking

For things like cabinets, TVs, or railings, forgetting to add backing means major headaches later.

5. Poor Layout

If your layout is off even half an inch, you'll have alignment issues that affect finishes.

Prevent these by following best practices, coordinating early with trades, and checking specs carefully.

Detailing for Drywall and Finishes

Metal stud framing plays a direct role in the quality of your interior finishes. Without solid framing behind, drywall can crack, bulge, or show fastener pops.

Best Practices:

- Use proper screw spacing, typically every 12" on walls, 8" on ceilings.

- Stagger joints across studs to avoid weak spots.

- Add corner reinforcements (L-beads, corner beads) to prevent cracking.

- For Level 5 finishes, ensure framing is plumb, square, and flat to within 1/8" over 10 feet.

Architects should clearly detail critical finish conditions like reveals, returns, or flush trims. Framers should flag any issues before board goes up.

Comparing Metal and Wood Framing: Costs, Time, and Performance

Let's break it down.

| Feature | Metal Stud Framing | Wood Framing |

|---|---|---|

| Material Cost | Moderate to high | Generally lower |

| Labor Speed | Faster (with experience) | Slower, but flexible |

| Fire Resistance | Excellent | Poor unless treated |

| Moisture Resistance | Excellent | Prone to rot |

| Environmental Impact | Recyclable steel | Renewable wood |

| Modifications | Requires tools | Easy to field-cut |

| Shrink/Warp Risk | None | High |

| Finish Compatibility | High | Variable |

Bottom line: Use wood for budget residential builds. Use metal for commercial work, high-rises, and fire-rated assemblies.

When Metal Studs Are Required by Code or Spec

There are situations where metal studs are required by building code or client specification.

Common Triggers:

- Fire-rated partitions in commercial and multi-family buildings

- High moisture environments

- Non-combustible construction classifications (Type I or II)

- Interior TI work where metal is already part of the base building

Always check spec sections 09210 or 05400 in your construction documents, and confirm requirements like:

- Gauge

- Coating (galvanized steel, for example)

- STC or fire-rating assemblies

- Integration with other systems

Should You Use Metal Stud Framing on Your Next Project?

If you're working on a commercial, multi-family, or urban renovation project, the answer is probably yes. Metal stud framing offers durability, fire resistance, and precision that wood can't match, especially in high-performance spaces.

It's lighter, straighter, and better suited for architectural specifications that demand crisp lines and code compliance. But remember: the system is only as good as its installation. The wrong gauge, poor fastening, or bad detailing will compromise your whole wall.

So check your specs. Understand your loads. And work with a team that knows how to use metal framing the right way.

FAQs

About CooperBuild Team

CooperBuild's team brings expertise in construction materials and building systems for residential and commercial projects.

Construction & Materials Specialists

Subscribe to Our Newsletter

Get the latest insights, trends, and news from the construction industry delivered straight to your inbox.

We respect your privacy. Unsubscribe at any time.