The Complete Guide to Cabinet Hinges: Types, Functions, and Uses

Cabinet hinge types include European (concealed) for hidden, modern doors, inset for flush-mounted doors, overlay (full, half, partial) for overlapping frames, wrap-around for added strength, and surface-mount for quick installs. Choosing the right hinge depends on cabinet construction, door style, and features like soft-close or self-closing.

Though small and often hidden, hinges are the mechanical heart of your cabinetry. Each hinge provides a precise pivot point, or "single degree of freedom" that enables smooth, reliable movement. Most homeowners and DIYers focus on finishes, colors, or materials for the cabinet faces but rarely dive into the mechanism that allows access to those beautifully crafted interiors. A misaligned hinge leads to rubbing doors, uneven gaps, and premature wear.

So, before you click that "Buy" button on your favorite hardware website or rush to your local hardware store, take a moment to explore the types, materials, and features that define quality cabinet hinges.

What is a Cabinet Hinge?

A cabinet hinge is a type of hardware that connects a cabinet door to its frame or box, enabling the door to swing open and closed. Used in kitchens, bathrooms, and storage areas, cabinet hinges come in styles such as concealed (European) for a hidden look or exposed for decorative appeal. The right hinge ensures smooth operation, proper alignment, and durability, with options like soft-close, self-close, and adjustable designs to suit different cabinet constructions.

Types of Hinges for Cabinet Doors

While some are engineered for clean design and seamless movement, others are designed for easy installation or retrofitting existing cabinet doors. Here's a look at the most common types:

1. Concealed Hinges

Photo from Tectus Hinges

These are often referred to as "European-style" hinges. They're hidden from view when the cabinet door is closed, making them the ideal choice for modern and minimalist kitchens or bedrooms. These hinges typically come with three-way adjustability (side-to-side, height, and depth), which allows for precision fitting even after the door is mounted.

2. Semi-Concealed Hinges

Photo from Rockler

These hinges are partially visible when the door is closed. They're a great option for face frame construction when you want a mix of aesthetics and ease of access. They offer a middle ground between fully exposed and completely hidden hardware.

3. Surface-Mounted Hinges

Photo from Rockler

These are mounted directly to the exterior of both the cabinet door and frame. They're incredibly easy to install, requiring no mortising or special tools. This type is often chosen for vintage or rustic applications where visible hardware enhances the cabinet's character.

Every hinge type has its pros and cons. The right choice depends on your cabinet style, the desired visibility, and the level of user convenience you're aiming for. Don't forget to factor in door weight and materials, as these will determine the durability and long-term performance of the hinge.

4. Inset Hinges

Inset hinges are built for doors that sit flush within the cabinet opening, creating a smooth, integrated look. These often require precise mortising and offer either exposed or concealed versions. They're perfect for high-end, custom cabinetry and areas where space or minimalism is a design priority.

5. Self-Closing Hinges

Photo from Rockler

Equipped with internal springs, self-closing hinges pull the door shut once it reaches a certain point. Unlike soft-close types, they typically do not dampen the closure, leading to a noticeable "snap" or "click." These are common in high-traffic kitchens, utility cabinets, or commercial environments where ensuring doors remain shut is essential.

6. Butt Hinges

A traditional hinge style featuring two rectangular leaves joined by a pin. Butt hinges require mortising into both the door and frame to sit flush. While not adjustable post-installation, they're extremely durable and ideal for solid wood or inset cabinet doors, especially in classical or traditional interiors.

7. Wrap Hinges

Photo from SOSS Door Hardware

Wrap hinges, often called wrap-around hinges, are a smart choice for achieving a seamless, concealed look on your cabinet doors. These hinges are designed so the door wraps around the cabinet frame when closed, resulting in a clean, unobtrusive appearance that's highly sought after in modern kitchen and bathroom projects. Wrap hinges are compatible with both face frame and frameless cabinets, making them a versatile option for a variety of cabinet styles.

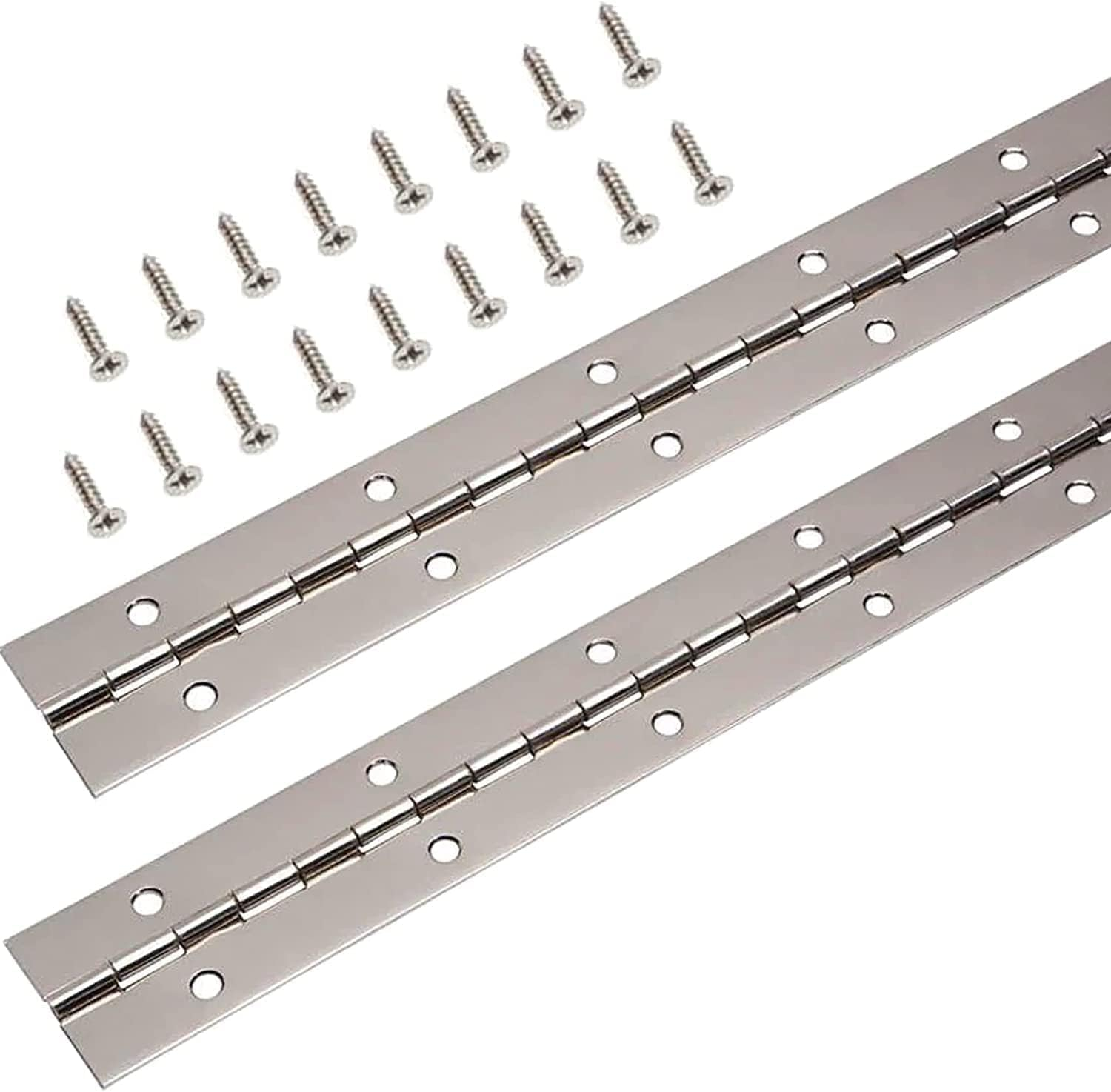

8. Continuous Hinges (Piano Hinges)

Running the entire height of the door, continuous hinges distribute weight evenly across the door edge. They're excellent for long, heavy cabinet doors or bench lids. These hinges are surface-mounted and don't require mortising, making installation straightforward.

9. Pivot Hinges

Installed at the top and bottom edges of the door, pivot hinges allow the door to rotate from a central axis point instead of swinging on a side-mounted leaf. These are ideal for glass cabinets, bar doors, and modern architectural installations where dramatic swing and minimal side clearance are desired.

10. SOSS (Invisible) Hinges

Photo from SOSS Door Hardware

These fully concealed cabinet hinges are mortised into both the door and cabinet frame, providing a perfectly flush, hardware-free exterior. Opening up to 180°, SOSS hinges are engineered for hidden doors, architectural panels, or premium cabinetry where aesthetics demand invisibility and high performance.

Comparison Table of Common Hinge Types

| Hinge Type | Design & Mechanism | Best Use Cases | Visibility | Installation Difficulty | Key Features / Benefits |

|---|---|---|---|---|---|

| 1. Concealed Hinges (European-Style) | Hidden cup in door, adjustable arm, often soft-close | Modern kitchens, minimalist bedrooms, frameless or face frame cabinets | Hidden | Moderate | 3D adjustability, clean look, soft-close options |

| 2. Semi-Concealed Hinges | Partially visible leaf mounts to face frame | Traditional cabinets, transitional designs | Partially visible | Easy to Moderate | Balanced aesthetics and functionality |

| 3. Surface-Mounted Hinges | External screw-mounted leaves; no mortising | Vintage/rustic cabinetry, DIY retrofits | Fully visible | Easy | Decorative, simple to install, no special tools required |

| 4. Inset Hinges | Mortised into door/frame; exposed or hidden variations | Custom cabinetry, inset door applications | Flush or hidden | Hard | Precise fit, refined look, ideal for space-saving designs |

| 5. Self-Closing Hinges | Internal spring snaps door shut automatically | Utility cabinets, high-traffic kitchen or commercial spaces | Varies | Moderate | Ensures doors stay shut, cost-effective |

| 6. Butt Hinges | Two metal leaves joined by a central pin; mortised into wood | Traditional solid wood doors, inset cabinetry | Visible | Moderate | Durable, load-bearing, classic appearance |

| 7. Wrap Hinges | Wraps around frame edge; semi-concealed or fully hidden | Modern kitchens/bathrooms, both frame types | Mostly hidden | Easy to Moderate | Clean finish, versatile, minimal hardware exposure |

| 8. Continuous Hinges (Piano) | Long hinge runs the full door height; surface-mounted | Long or heavy cabinet doors, bench lids, workstations | Visible edge | Easy | Even weight distribution, strong support |

| 9. Pivot Hinges | Rotates on a top/bottom axis point instead of side mounting | Glass cabinets, modern bar doors, hidden panels | Mostly hidden | Hard | Smooth swing, ideal for tight clearances |

| 10. SOSS Hinges (Invisible) | Fully concealed mortised hinge with 180° opening range | High-end flush cabinetry, secret doors, architectural panels | Fully hidden | Complex | Ultra-clean finish, security, smooth full-range opening |

Concealed Hinges for Modern Cabinets

If your design vision is clean, sleek, and modern, concealed cabinet hinges are your best choice. Their hidden design provides a seamless look that's particularly popular in urban and contemporary settings like modern kitchens or luxury bedroom wardrobes.

Most concealed hinges are cup-style, mounted inside a 35mm hole bored into the cabinet door. This makes them practically invisible when the door is closed. More importantly, they often include soft-close dampers for whisper-quiet operation, a game-changer in busy households. Many NYC homeowners installing new Cooperbuild cabinetry in high-rise apartments prefer concealed hinges for their noise-reducing capability and minimalistic design.

But concealed cabinet hinges aren't one-size-fits-all. You'll need to consider:

- Overlay style (full, partial, or inset)

- Face frame or frameless cabinet construction

- Door weight and thickness

- Opening angle (standard 110°, or up to 170° for specialty applications)

Concealed hinges also come in various finishes, from brushed nickel to matte black ensuring a cohesive look with other hardware like handles, pulls, and knobs.

Face Frame Construction Explained

Face frame construction is the traditional method of cabinet making in the U.S. It involves a 1.5" to 2" wide frame attached to the front of the cabinet box. This method adds structural integrity and provides a solid surface for attaching hinges, making it ideal for both concealed and semi-concealed hinge types.

When working with face frame cabinets, you need hinges that mount to the face frame rather than the cabinet side. Compact concealed cabinet hinges are often designed specifically for this setup, offering enhanced adjustability and a flush finish. Alternatively, surface-mount or semi-concealed hinges can offer visual appeal and simplicity for vintage-style or farmhouse kitchens.

One of the critical considerations in face frame construction is overlay. You'll need to calculate how much the cabinet door will cover the frame when closed. For a full overlay, choose a straight-arm concealed hinge. For a partial overlay, opt for a half-crank hinge. And for inset doors, look for either butt hinges or fully inset concealed cabinet hinges with zero offset.

Precision is key here. Any error in measurements can lead to misaligned doors, unwanted gaps, or doors that won't stay closed. Always use a combination square, level, and marking jig to get the most accurate results. When installed correctly, face frame construction not only enhances cabinet stability but also ensures long-term convenience and ease of access.

Cabinet Door Styles & Hinge Pairing

When it comes to selecting cabinet hinges, door style isn't just a minor aesthetic decision, it defines the very nature of your hinge choices. Cabinet doors come in various styles: full overlay, partial overlay, inset, and lipped. Each of these interacts differently with the cabinet frame and affects which hinge will work best.

Full Overlay Doors

These doors cover the entire face frame or box edge, giving the cabinetry a seamless and modern look. They pair perfectly with concealed cabinet hinges and are a favorite for frameless cabinetry, common in Euro-style kitchens.

Partial Overlay Doors

Also known as half overlay, these doors cover only part of the cabinet face, revealing some frame around the door. They work best with half-crank concealed or semi-concealed hinges.

Inset Doors

Here, the door sits entirely within the cabinet opening, flush with the face frame. These demand a high level of installation precision and typically use butt or inset concealed hinges.

Lipped Doors

Lipped doors have a rabbet cut into the door edge, allowing it to partially sit within the opening while overlaying the frame. Offset surface-mount or semi-concealed hinges are often ideal.

When choosing hinges for any of these door styles, also consider the overall goal of your project. Are you going for maximum access, a decorative exposed look, or a hidden minimalist design? Matching your hinge to the door's style ensures not only perfect operation but also visual harmony.

Hinge Functionality and Special Features

Beyond simply opening and closing cabinet doors, hinges today are packed with features designed to enhance usability, safety, and visual appeal.

Soft-Close Hinges

These are equipped with built-in hydraulic dampers that slow the door down before it makes contact with the frame, providing a silent, cushioned close. No more slamming! Soft-close hinges are ideal for families with children or for kitchen environments where noise control is key. They also extend the life of both the hinge and the cabinet door by reducing impact.

Self-Closing Hinges

These include a spring mechanism that pulls the door shut when it reaches a certain point. Unlike soft-close, they don't dampen the movement, so you'll often hear a small thump. They're budget-friendly, widely used in utility rooms or closets, and are great for ensuring doors stay closed without latches.

Adjustable Hinges

These offer the ability to fine-tune door alignment after installation. Most concealed cabinet hinges provide three-way adjustability (horizontal, vertical, and depth). This is especially valuable in environments with fluctuating humidity levels like kitchens or bathrooms where wooden doors may shift slightly over time.

Quick-Release (Clip-On) Hinges

A popular subcategory of concealed cabinet hinges, these allow you to snap the door off the cabinet without unscrewing the mounting plates. This makes project assembly and maintenance easier, especially when installing multiple cabinets.

High-Angle Hinges

These provide opening ranges beyond the standard 110°, sometimes up to 170°, making them ideal for corner cabinets or wider access needs. They are most useful in kitchen corner units or wardrobe systems.

When shopping on a hardware website or browsing a store, look for labels like "soft-close," "clip-on," or "3D adjustable." These features reflect thoughtful engineering that improves the daily user experience and ensures long-term reliability. Cooperbuild's design team often recommends hinges with at least two advanced features to maximize both convenience and performance.

Installation Methods and Tools

A misaligned hinge can make a door hang crooked, scrape the frame, or fail to close completely. To get it right, it's vital to match the installation method with the hinge type and cabinet construction (face frame or frameless).

Surface Mounting

This is the simplest step in hinge installation. Surface-mounted hinges are attached directly to the outside of the door and cabinet box with screws. No special drilling is required, making them ideal for DIY or quick projects.

Mortising

Used primarily for butt hinges and some inset hinges, mortising involves carving out a recess (or mortise) into the cabinet door and frame. This allows the hinge to sit flush and ensures a clean finish. Tools needed include a chisel or router and a steady hand.

Cup-Boring for Concealed Hinges

Most European-style concealed cabinet hinges require a 35mm diameter cup hole drilled into the back of the cabinet door. A Forstner bit is typically used for this. Precision is critical—too deep, and the hinge won't fit correctly; too shallow, and it may not sit flush.

Tools Required

- Power drill

- Forstner bit (for concealed hinges)

- Screwdriver (manual or electric)

- Measuring tape

- Pencil or marking jig

- Level

- Combination square

- Safety goggles

Pro Tips

- Always double-check measurements.

- For heavy or large doors, install an extra hinge in the center.

- Shim doors during installation to maintain even spacing (called a "reveal").

At Cooperbuild, we recommend creating a test jig or using a reference cabinet door to practice before final installation. This simple step can prevent misdrilled holes and save materials and time.

Measuring and Fitting Cabinet Hinges

Accuracy is everything in hinge installation. An incorrectly placed hinge can throw off door alignment, cause rubbing, or reduce the hinge's lifespan due to improper weight distribution. Here's how to get the measurements right:

1. Mark the Hinge Locations

Typically, hinges are placed 3.5″ from the top and bottom of the door. For taller doors (over 36″), add a third hinge in the center for stability.

2. Calculate Overlay (If Applicable)

For overlay doors, find out how much of the frame the door will cover. Measure the cabinet opening, subtract it from the door width, and divide by two. This figure is your overlay. Many hinges are designed for specific overlay sizes.

3. Mark Cup Hole Center (Concealed Hinges)

Most concealed cabinet hinges are centered 22mm from the edge of the door to the center of the cup hole. Use a jig or marking tool to ensure repeatable accuracy.

4. Drill Cup Holes

Use a drill with a 35mm Forstner bit. Drill slowly and steadily to avoid damaging the wood. Mark your depth on the bit using masking tape.

5. Dry-Fit Before Screwing

Always test-fit the hinge into the drilled hole before attaching it with screws. This prevents errors and allows you to correct any misalignments before they become permanent.

Getting these steps right from the beginning will ensure a perfect door swing, minimize friction, and give your cabinetry a clean, professional finish. Cooperbuild's field teams use custom jigs and digital calipers for high-precision projects, but most homeowners can achieve great results with a steady hand and patience.

Transform Your Space with Precision-Built Cabinetry—Crafted Right Here in NYC

If you're planning a renovation or new build, don't overlook this small but mighty hardware. CooperBuild's in-house millwork shop fabricates custom cabinetry with industry-leading precision. We don't just install hinges, we engineer entire cabinet systems where every detail is aligned, tested, and fine-tuned for flawless function.

Ready to get started on your next cabinet project? Reach out to Cooperbuild for custom millwork solutions, hardware selection expertise, and turn-key cabinetry installation across New York City.

Looking to go beyond traditional hinges? Discover our deep dive into pocket door systems like Blum's REVEGO, a sleek, integrated sliding solution that takes modern cabinetry to the next level.

FAQs

About CooperBuild Team

CooperBuild's in-house millwork team brings expertise in precision cabinet fabrication, hardware selection, and installation for luxury projects across NYC.

Custom Millwork & Hardware Specialists

Subscribe to Our Newsletter

Get the latest insights, trends, and news from the construction industry delivered straight to your inbox.

We respect your privacy. Unsubscribe at any time.